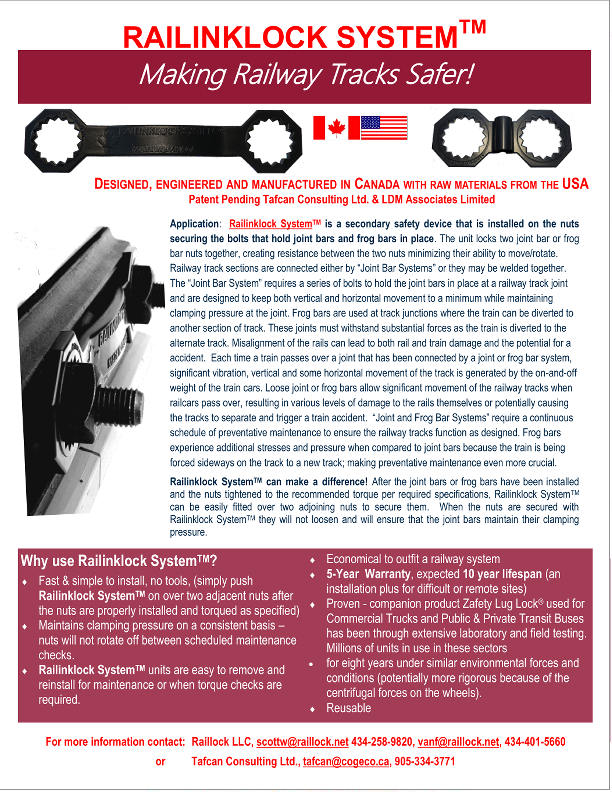

Railinklock System is applicable for both standard & electrified rail – only specified products may be used on electrified rail.

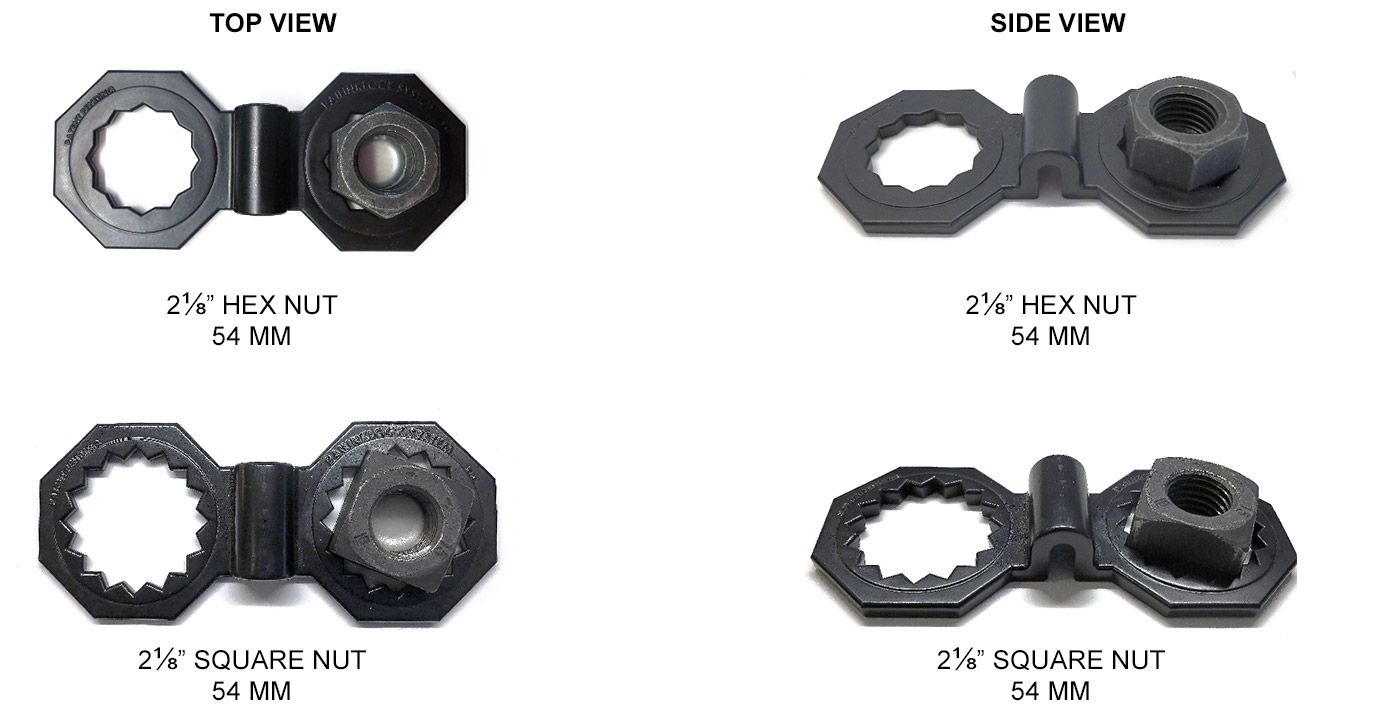

Railinklock units are made of a resilient plastic capable of withstanding rigorous environmental conditions and feature a ribbon shaped central section and a wider round section located at each end of ribbon shaped central section. The ribbon shaped central section (smaller on the frog units) is generally in the shape of an arc, smooth on the front but with reinforcing ribs on the back creating a semi- rigid section that can be bent, twisted or flexed, to a certain degree during installation, but remains sufficiently rigid during use to prevent the nuts from moving once they are installed. The size and shape of the arc is dictated by the distance between the nuts. The openings have a series of teeth which are adapted and beveled in such a way to make it easier to be fitted around the shoulders of a rail bolt nut so as to provide a friction fit. The farther down the nut the unit is pushed the tighter the friction fit will be.

Material Selection

Standard Rail Material Description

The plastic material is based on previous experience with the Zafety Lug Lock®product and was developed working in conjunction with our plastic design engineers. The design engineered plastic is similar to products developed for the automotive industry to resist many types of industrial chemicals, oils and solvents (see Chart 1.) and environmental conditions. Generally, the material used will create a final product that has mechanical and physical properties such as exceptional toughness and resilience, high resistance to creep, impact and flex fatigue, flexibility at low temperatures and good retention of properties at elevated temperatures. Specialty engineering resin is designed to perform in temperature conditions of -400C (-400F) to 850C (1850F). Special grades include heat stabilized, flame retardant and extrusion grades. Material includes UV protection additives, and heat stabilizers flame retardants. It has nominal durometer hardness of 44D. This resin has been proven to be effective when used in demanding applications in the automotive, fluid power, electrical/electronic, consumer goods, appliance and power tool, sporting goods, furniture, industrial and off-road transportation/equipment industry.

The Railinklock System™ raw material has additional UV resistance and the formulation was developed to deter ingestion by small animals and rodents.

The colour choice of black was specifically selected to blend in with track surroundings to minimize any curiosity or desire to remove them by unauthorized persons.

A Manufacturer’s five (5)-year warranty covers any manufacturing defects however, because of the specialized plastic composition it is expected to have a lifespan of 10+ years.

Electrified Rail Material Description

With a need identified for Electrified Rail it was important to upgrade the material to include additional properties ensuring the material had increased flame-retardant properties and was antidrip to meet the requirement of UL94 V-0. In addition to the properties and capabilities of the Standard Rail material the resin used for Electrified Rail is a medium modulus flame retardant and antidrip that meets the requirement of UL94 V-0.

The electrified rail product also carries a Manufacturer’s five (5)-year warranty covers any manufacturing defects however, because of the specialized plastic composition it is expected to have a lifespan of 10+ years.

Railinklock System Part Numbers

| Standard Rail - Standard Grade Units for non-electrified rails | Part Number | Electrified Rail - Electric Grade Units for electrified rails | Part Number |

|---|---|---|---|

| Joint bar 11-inch spacing square nut size 41 mm (1 5/8 inches) | SRJ11-SQ41 | Joint bar 11-inch spacing square nut size 41 mm (1 5/8 inches) | ERJ11-SQ41 |

| Joint bar 12-inch spacing square nut size 41 mm (1 5/8 inches) | SRJ12-SQ41 | Joint bar 12-inch spacing square nut size 41 mm (1 5/8 inches) | ERJ12-SQ41 |

| Joint bar 12-inch spacing square nut size 44 mm (1 3/4 inches) | SRJ12-SQ44 | Joint bar 12-inch spacing square nut size 44 mm (1 3/4 inches) | ERJ12-SQ44 |

| Joint bar 13-inch spacing square nut size 41 mm (1 5/8 inches) | SRJ13-SQ41 | Joint bar 13-inch spacing square nut size 41 mm (1 5/8 inches) | ERJ13-SQ41 |

| Frog bar 5 ¼-inch spacing square nut size 54 mm (2.14 inches) | SRF5-SQ54 | Frog bar 5 ¼-inch spacing square nut size 54 mm (2.14 inches) | ERF5-SQ54 |

| Frog bar 5 ¼-inch spacing hexagonal nut size 54 mm (2.125 inches) | SRF5-HX54 | Frog bar 5 ¼-inch spacing hexagonal nut size 54 mm (2.125 inches) | ERF5-HX54 |

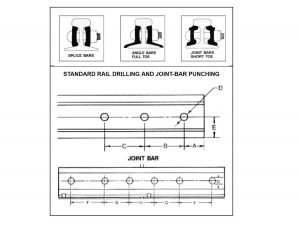

Tee Rail Chart

| Tee Rail | A | B | C | D | E | Bar Length (") | Bar Weight (PR) | Bar Punching (") | Common Type | |

| 4-Hole | 6-Hole | FxGxHxGxF | ||||||||

| 100 lb. RE | 2- 11/16 | 5- 1/2 | - | 1- 3/16 | 2- 45/64 | 22 | 51.9 | - | 5 1/2 x 5 1/2 x 5 1/2 | Angle F.T. |

| 100 lb. ARAA | 2- 11/16 | 5- 1/2 | - | 1- 3/16 | 2- 3/4 | 22/33 | 53.5 | 80.3 | 5 1/2 x 5 1/2 x 5 1/2 | Angle F.T. |

| 100 lb. ASCE | 2- 15/16 | 6 | - | 1- 3/16 | 2- 65/128 | 24 | 63.2 | - | 5 x 5 1/8 x 5 | Angle F.T. |

| 115 lb. RE | 3- 1/2 | 6 | 6 | 1- 3/16 | 2- 7/8 | 25/36 | 69.4 | 99.8 | 6 x 6 x 7 1/8 x 6 x 6 | Angle F.T. |

| 132 lb. RE | 3- 1/2 | 6 | 6 | 1- 5/16 | 3- 3/32 | 24/36 | 71.0 | 106.5 | 6 x 6 x 7 1/8 x 6 x 6 | Angle F.T. |

| 136 lb. RE | 3- 1/2 | 6 | 6 | 1- 5/16 | 3- 3/32 | 24/36 | 71.0 | 106.5 | 6 x 6 x 7 1/8 x 6 x 6 | Angle F.T. |

Railinklock System™ simplifies the process of inspecting – torque checks can be completed without removing the units.

Top view – 3-foot bar – four “outer” nuts are secured.

Side view – 3-foot bar – alternate nuts are secured – live track

Side view Frog Bar unit

Joint Bar Units

Frog Bar Units